PRODUCTS

Product Category

High pressure valve

Item No.:

Category:

Specifications

Disk coupling is a power transmission device for non-contact air separation transmission by the interaction principle of strong magnet’s suction and repulsive force.

Tel: +86 17788593048

E-mail:dlhaa@jinyiyang.com

Keywords: Coupling,Disk Couplings,Magnetic Agitator

Description

Permanent magnet synchronous coupling can use the magnetic force between internal and external rotors to transfer torque.The precision loss caused by mechanical wear can be effectively controlled and the service life is longer.

This product can be customized according to customer installation requirements. Accessories can be used on older models to replace conventional sealed couplings to meet production requirements.

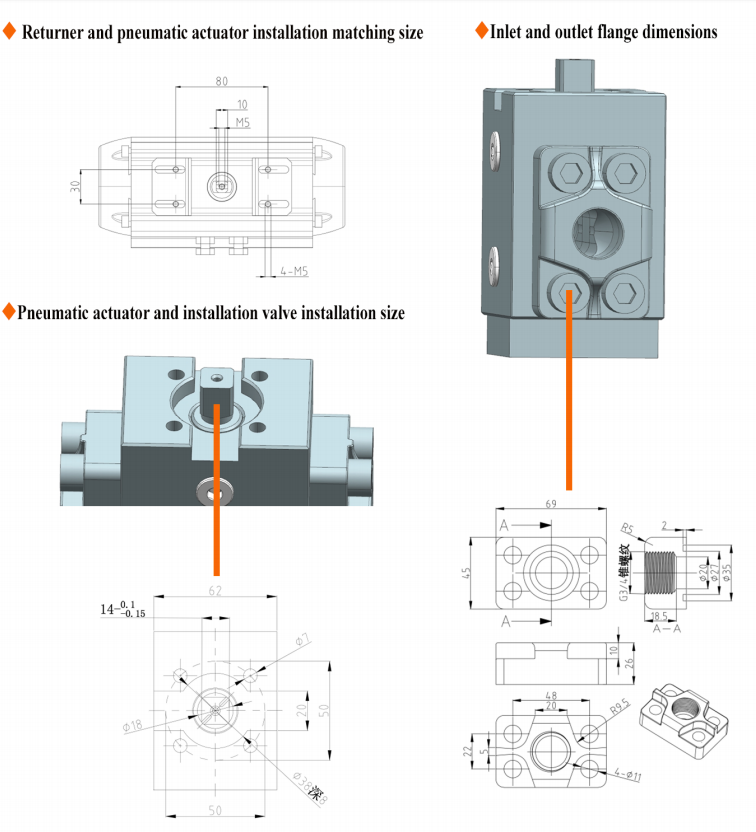

High pressure valve has been widely used in superhard material manufacturing, chemical industry, petrochemical industry, processing technology, isostatic pressure processing, ultra-high static

pressure extrusion, powder metallurgy, metal forming and geophysical, geological research and other fields.

It can be used to control the flow of air, water, steam, various corrosive media, mud, oil, liquid metal and radioactive media and other types of fluids. The opening and closing part is a disc shaped valve plate that rotates around its own axis in the valve body to achieve the purpose of opening and closing or adjusting. The high pressure valve mainly plays the role of cutting and throttling on the pipeline.

Characteristics of high pressure valve

1. The best design product for DUThigh-pressure casting equipment.

2. Controlled by pneumatic actuator to prevent backflow.

3.With ultra-precision equipment production to ensure product life.

4. Under the action of pneumatic actuator, super fast high pressure rising time is generated

In order to improve the ability of ultra-high pressure valve erosion wear, usually choose the following corrosion resistant materials with the following characteristics.

1.High hardness

2.Acid corrosion protective film

3.High yield point, good stability

4.High fatigue strength

To improve the properties of materials, one is alloying, by changing the chemical composition of steel to develop new materials with special properties. The second is to use appropriate heat treatment. Without changing the chemical composition of the steel, different heating, insulation and cooling are applied to the steel in the solid state to change the structure of the steel and improve the properties of the material.

The high-pressure valve of our company mainly uses 38CrMoALA, which is a kind of high-grade nitride steel quality, has high surface hardness, wear resistance and fatigue strength, and has

good heat resistance and corrosion resistance, hardenability is not high. After going through nitriding, quenching and other processes, this product will have better wear resistance, fatigue

resistance, corrosion resistance and high temperature resistance.

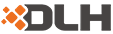

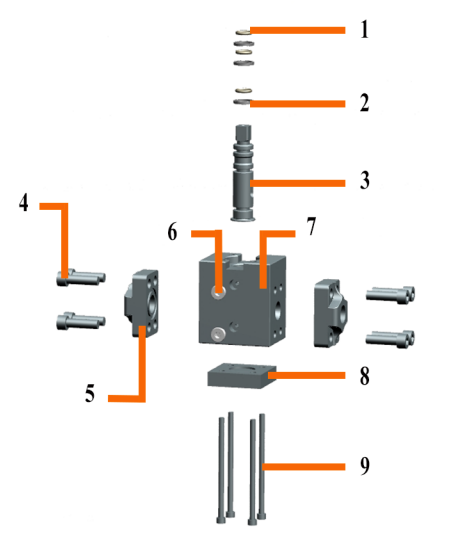

General assembly drawing

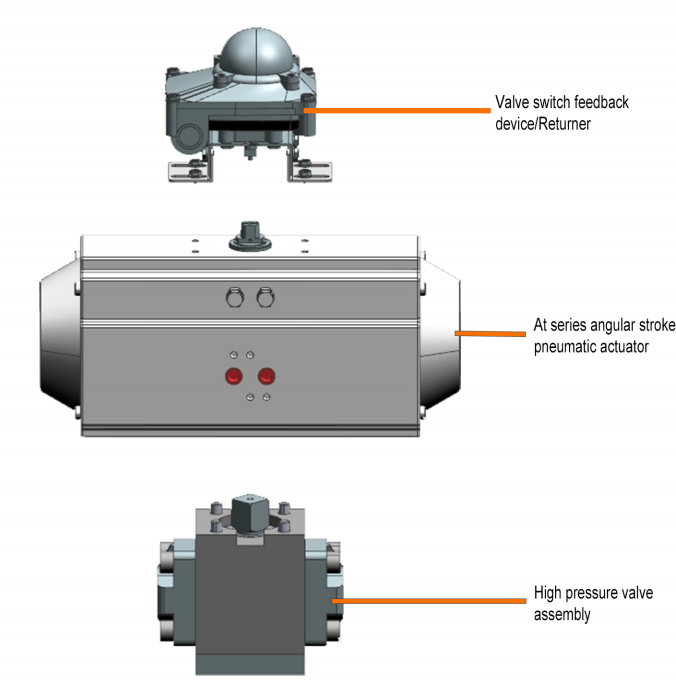

Structure diagram of high pressure valve

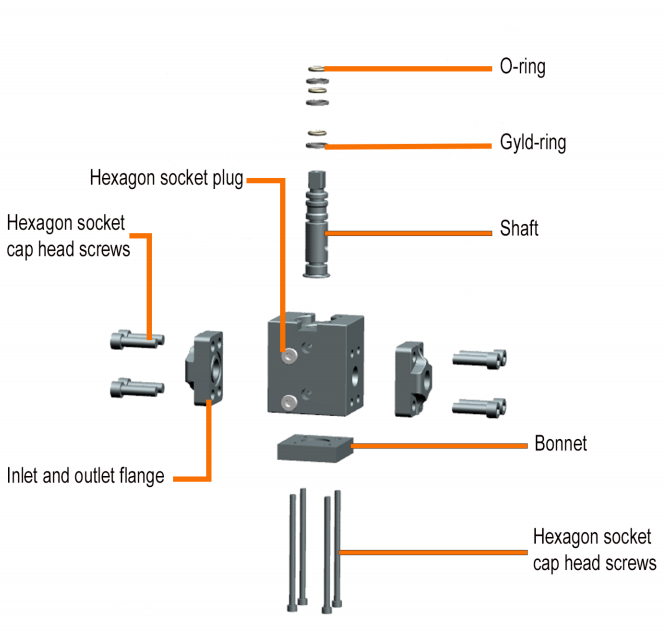

Assembly steps

Product Specification

|

Serial number |

Quantity |

Part name |

Specifications |

|

1 |

3 |

O-ring |

φ18.2×φ14×3.2 |

|

2 |

3 |

Glyd-ring |

φ22×φ18.2×3.2 |

|

3 |

1 |

Valve rod |

φ24×103 |

|

4 |

8 |

Soket headcapscrew |

M10×35 |

|

5 |

2 |

Inlet &outlet frange |

69×45×26 |

|

6 |

2 |

Hexagonsocket plug |

G1/4 |

|

7 |

1 |

Valve body |

90.5×80×62 |

|

8 |

1 |

Bonnet |

60×60×15.5 |

|

9 |

4 |

Hexagon socketcapscrews |

M6×110 |

Online Inquiry

Thank you for your attention to us. If you have any needs or comments, please leave us a message.