PRODUCTS

Product Category

Mixing Head

Item No.:

Category:

Specifications

Disk coupling is a power transmission device for non-contact air separation transmission by the interaction principle of strong magnet’s suction and repulsive force.

Tel: +86 17788593048

E-mail:dlhaa@jinyiyang.com

Keywords: Coupling,Disk Couplings,Magnetic Agitator

Description

Permanent magnet synchronous coupling can use the magnetic force between internal and external rotors to transfer torque.The precision loss caused by mechanical wear can be effectively controlled and the service life is longer.

This product can be customized according to customer installation requirements. Accessories can be used on older models to replace conventional sealed couplings to meet production requirements.

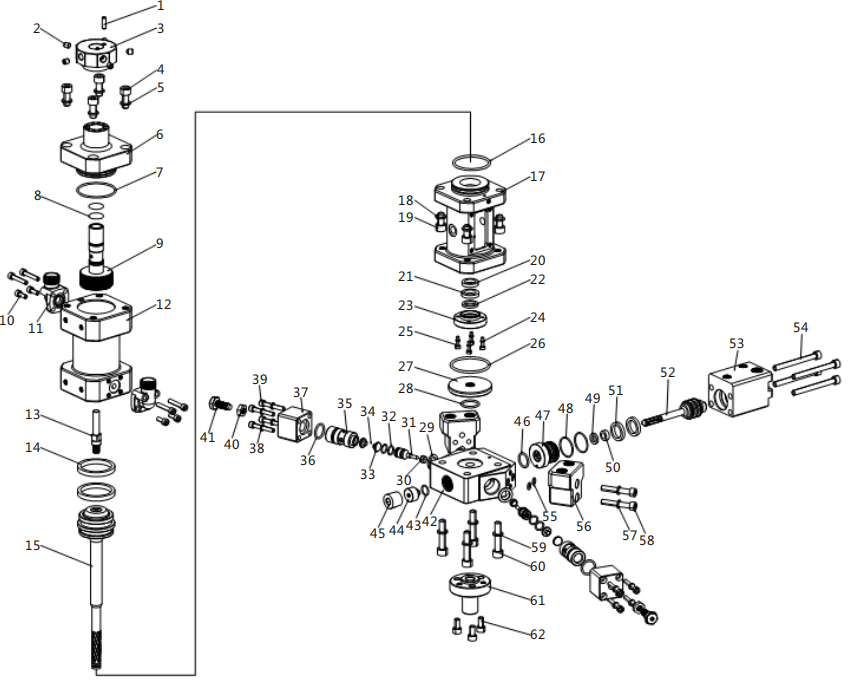

|

Number |

Name |

Quantity/piece |

Nunber |

Name |

Quantity/piece |

|

1 |

Hexagon socket setscrew |

1 |

32 |

O-ring |

4 |

|

2 |

Hexagon socket setscrew |

5 |

33 |

Spring seat |

4 |

|

3 |

Stroke adjustment knob |

1 |

34 |

Rectangular spring |

2 |

|

4 |

Hexagon socket headcapscrew |

4 |

35 |

One-way valve body |

2 |

|

5 |

Spring washer |

4 |

36 |

O-ring |

2 |

|

6 |

Rear end cover oflarge cylinder |

1 |

37 |

Pressure regulating valve seat |

2 |

|

7 |

O-ring |

1 |

38 |

Spring washer |

8 |

|

8 |

O-ring |

2 |

39 |

Hexagon socket headcapscrew |

8 |

|

9 |

Stroke adjusting valve element |

1 |

40 |

Locknut |

2 |

|

10 |

Hexagon socket headcapscrew |

8 |

41 |

Nozzle pressure adjusting screw |

2 |

|

11 |

Oil inletjoint oflarge cylinder |

2 |

42 |

Mixing valve body |

1 |

|

12 |

Large oil cylinder |

1 |

43 |

O-ring |

1 |

|

13 |

Travel limitmandrel |

1 |

44 |

Plug core |

1 |

|

14 |

UN sealingring forpiston |

2 |

45 |

Plug |

1 |

|

15 |

Largepiston |

1 |

46 |

O-ring |

1 |

|

16 |

O-ring |

1 |

47 |

Small oil cylinder positioningcore |

1 |

|

17 |

Coupling seat |

1 |

48 |

O-ring |

2 |

|

18 |

Spring washer |

4 |

49 |

OED Steffen |

1 |

|

19 |

Hexagon socket headcapscrew |

4 |

50 |

UN sealing ringforpistonrod |

1 |

|

20 |

UN sealing ringforpistonrod |

1 |

51 |

UN sealingring forpiston |

2 |

|

21 |

OED sealretainingringB |

1 |

52 |

Smallpiston |

1 |

|

22 |

OED Steffen |

1 |

53 |

Small oil cylinder |

1 |

|

23 |

Gland |

1 |

54 |

Hexagon socket headcapscrew |

4 |

|

24 |

Spring washer |

4 |

55 |

O-ring |

4 |

|

25 |

Hexagon socket headcapscrew |

4 |

56 |

Feed interface |

2 |

|

26 |

O-ring |

1 |

57 |

Spring washer |

4 |

|

27 |

Copper sleeve |

1 |

58 |

Hexagon socket headcapscrew |

4 |

|

28 |

O-ring |

1 |

59 |

Spring washer |

4 |

|

29 |

Valve bodygasket |

2 |

60 |

Hexagon socket headcapscrew |

4 |

|

30 |

Nozzle opening |

2 |

61 |

Outlet |

1 |

|

31 |

One-way valve element |

2 |

62 |

Hexagon socket headcapscrew |

3 |

|

Mixingheadparameters |

||||

| Mixing ratio model |

Closing the mold(g/s) |

Open mold(g/s) |

||

|

1:1 |

1:2 |

1:3 |

||

|

10-14-2K |

50-450 |

60-380 |

80-340 |

60-250 |

|

12-18-2K |

130-1100 |

140-900 |

150-750 |

120-500 |

|

16-25-2K |

370-3500 |

380-2300 |

600-2100 |

400-900 |

|

16-25-4K |

320-3800 |

430-2300 |

450-1800 |

400-800 |

Online Inquiry

Thank you for your attention to us. If you have any needs or comments, please leave us a message.